The power of the EverSense® solution lies in its ability to integrate and process any type of automated measurement to provide relevant indicators and dashboards to a range of different stakeholders.

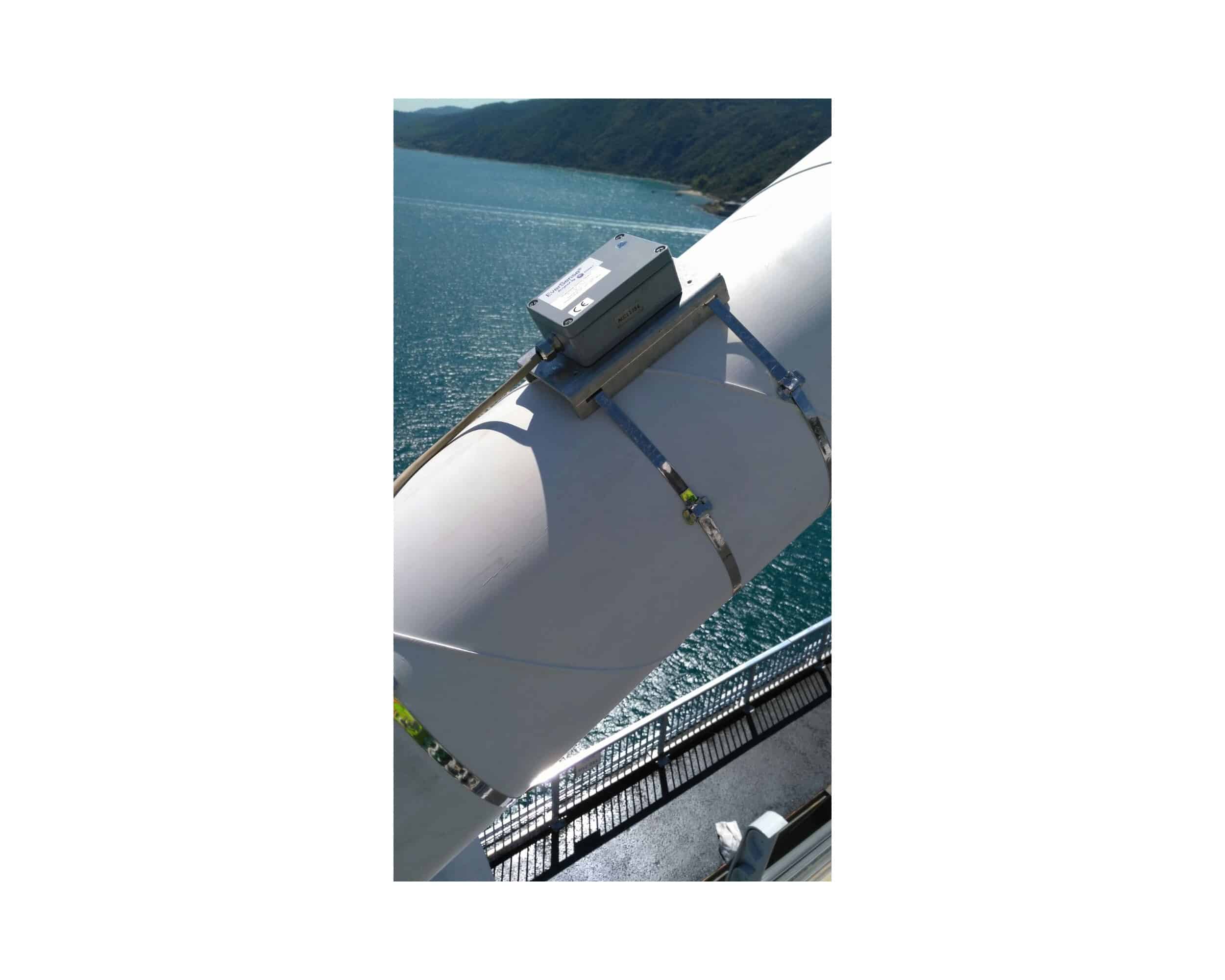

Our systems are deployed worldwide to inspect and monitor structures such as bridges, offshore platforms, wind turbines and nuclear facilities.

EverSense®: monitoring and analysis

A unique expertise in the instrumentation of stay-cabled and prestressed concrete structures

We offer turnkey systems worldwide, backed up by multi-year maintenance contracts. Installation durability has always been a core commitment at Sixense.

Systems that have been installed for more than 10 years show an operating rate in excess of 99 %.

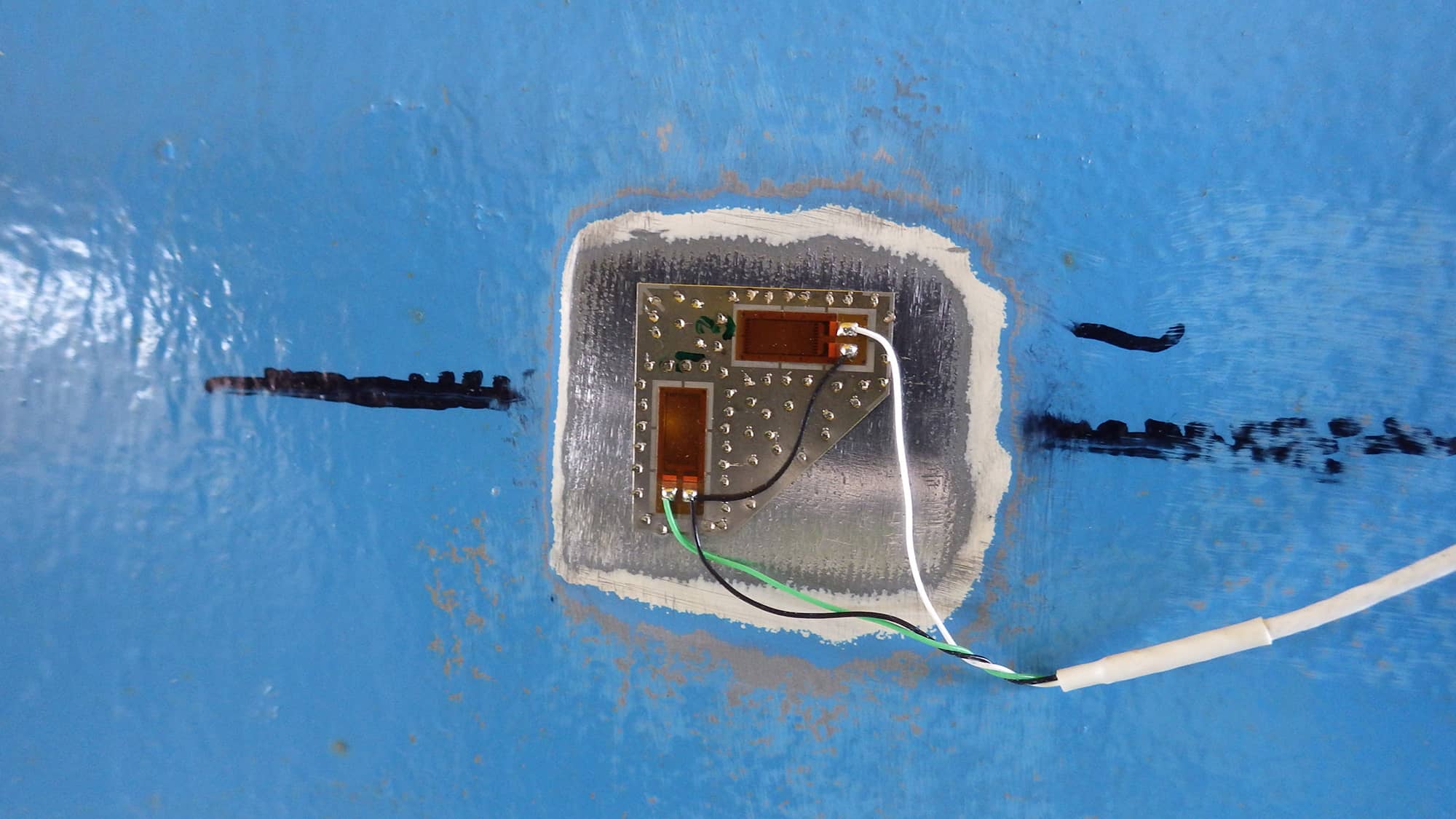

Unique expertise in the instrumentation of cabled and prestressed concrete structures

The competence of our teams gives us the ability to recommend solutions tailored to solving specific problems:

- Corrosion and detection monitoring of reinforced and prestressed concrete structures

- Crack monitoring

- Fatigue risk monitoring

- Early-stage detection of scouring

- Risk of gantry structure collapse

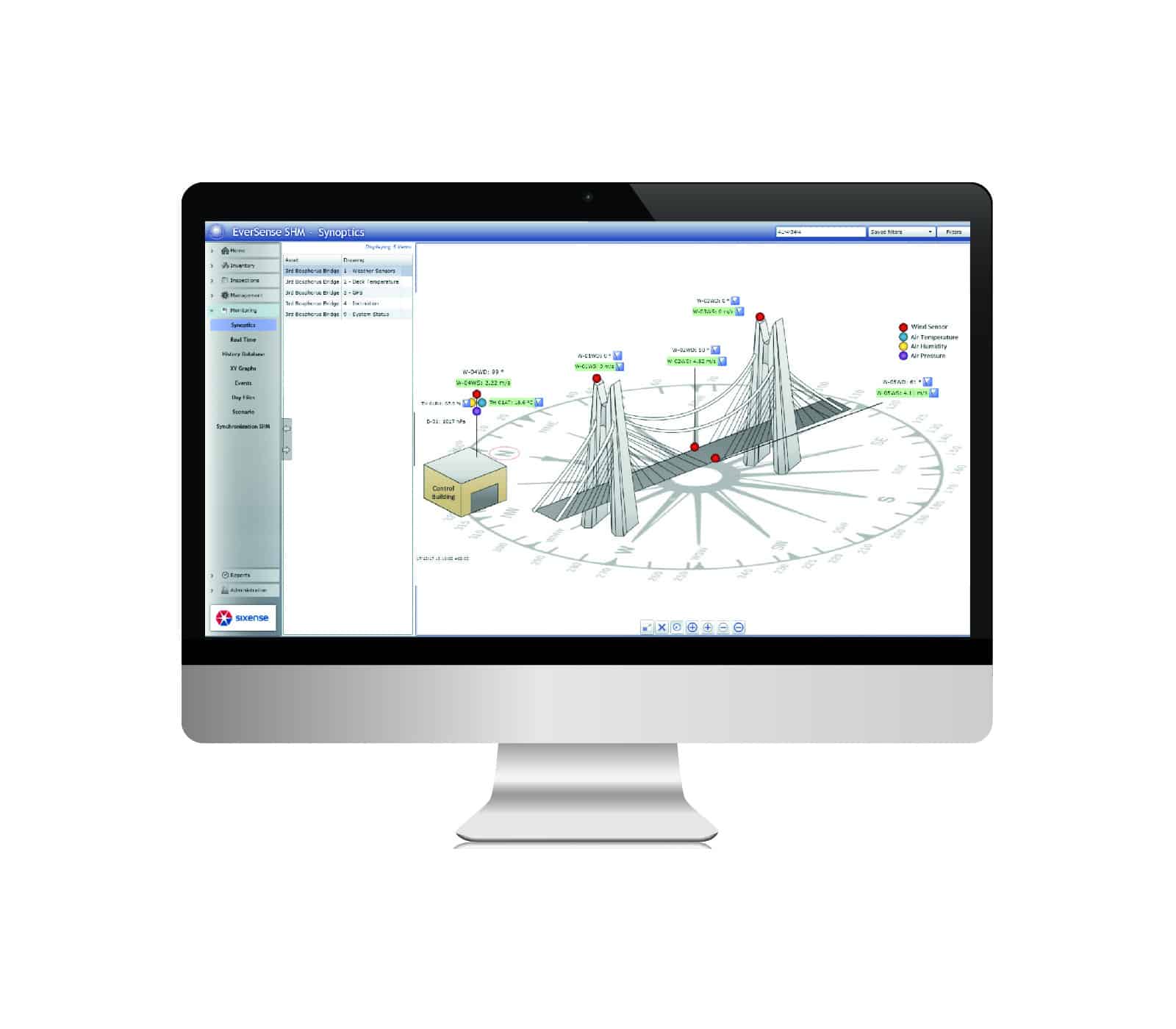

EverSense® software

The members of our team are specialists in Civil Engineering, Metrology, Electronics and Computer Science.

This broad skill set gives us a clear understanding of client needs on which to develop and recommend appropriate software solutions.

EverSense® comprises a series of modules, ranging from real-time data acquisition and alert management to data exploitation via a web server.

Sensors designed to meet your needs

Sixense offers a comprehensive range of structural, hydraulic, environmental and other measurement sensors to monitor:

- cable-stayed and prestressed structures

- structures at risk of corrosion

- structures at risk of scouring

- structures at risk of ageing by fatigue

As part of providing a comprehensive, efficient and effective monitoring service, we combine many different technologies, including: electrical, electromagnetic, fibre optic, vibrating string strain gauge, acoustic and ultrasonic sensors, radar and laser measurement solutions, fully equipped surveying solutions and InSAR satellite measurement.

Robust and versatile acquisition systems

For even faster and more cost-effective installation, Sixense offers a range of battery and solar powered wireless scanners use radio frequencies and GSM for data transmission.

Sixense also offers heavy-duty systems with the ability to capture data from hundreds of sensors and deliver a long-term operating rate in excess of 99 %.

Our solutions

Scouring monitoring

60% of the world’s structural failures occur as a result of floods and scouring.

Early detection of scouring is the best solution for avoiding sudden and unexpected structural failures.

Co-developed with IFSTTAR, our method is the only solution that provides permanent continual monitoring and early-stage detection.

Why choose our SHM solutions?

Our solutions facilitate proactive decision-making so that you can:

- View the status of your structures in real time

- Predict and optimise maintenance needs

- Ensure user safety

- Extend the operating service life of your structures